- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Size: 1.36

- Place of Origin: China

- Brand Name: hengzhong

- Model Number: XMQ460 * 600

- Weight: 560.000 kg

- :

- :

- :

- :

- :

- :

- :

- :

- :

- :

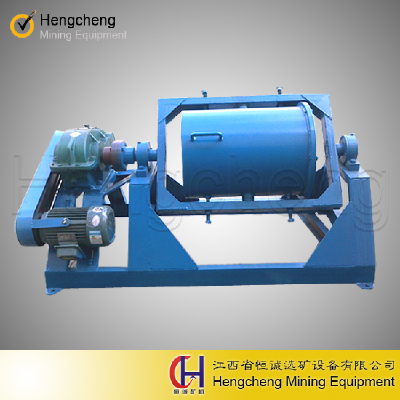

laboratory test equipment small ball mill for lab mineral processing grinding

Specification

XMQ460 * 600 cylinder ball mill, is fully enclosed type dry, wet amphibious continuous grinding

equipment, for building materials (especially cement and ceramic industrial) refractory materials,

metallurgy, coal, light industrial chemical, agricultural and industrial laboratories and a half or

othersmall industrial mill fine materials

are optional ore research work with, is between continuous grinding and continuous grinding

betweengood a transitional grinding equipment. The experiment work is also geology, artificial heavy sand mineral separation before a more appropriate grinding equipment

Application

Ball mill is the key equipment for grinding after the crushing process, which is widely used in

the manufacture industries, such as cement, silicate, new building material, refractory material,

fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and

wet grinding for all kinds of ores and other grind-able materials.

Working principle

The ball mill is horizontal cylindrical rotation device, driven by brim gearwheel. There are two

chambers and grid. Material goes into the first chamber through the feeding inlet. Inside the first

chamber, there are stage liners and ripple liners as well as steel balls. The shell rotates so as

to generate electricity, and this force brings ball to a certain height and then balls drop down by

gravity, the impact is the grinding force to the material. After the primary grinding, materials go

into the second chamber through segregate screen. In the second chamber, there are flat liners

and steel ball, after the secondary grinding, material is discharged from the discharging.

The machine is composed by feeding part, discharging part, rotation part and driving part (reducer, small driving gear, electric motor and electric control). The quill shaft adopts cast steel part and

the liner is detachable. The rotation big gearwheel is made by cast hobbling processing and the

drum is equipped with wear-resistant liner, which has good wear resistance. The machine is with stable and reliable working condition.

Features

1. Wide usage, simple structure, convenient maintenance;

2. Big capacity, continuous working;

3. Body liners and grinding medium could be made of various of materials, good corrosion

resistance;

4. Easy installation, adjustment, and operation

technical parameters

name | unit | ||||||

Cylinder(dia × length) | Φ460×600 | Mm | |||||

Cylinder volume | 100 | L | |||||

Cylinder speed | 48 | r/min | |||||

Feed Particle | 2-5 | mm | |||||

Feeding amount of each time | 15-30 | kg | |||||

Processing Capacity | Particle | 0.83 | 0.30 | 0.21 | 0.15 | 0.074 | Mm |

Mesh Size | 20 | 48 | 65 | 100 | 200 | mesh | |

Capacity | 350 | 274 | 130 | 90 | 45 | Kg/h | |

Dimension | 1600/850/1000 | Mm | |||||

Weight | 560 | kg | |||||

Jiangxi Hengcheng Mining Equipment Co.,Ltd is always going for the best quality and perfect service for customers

and it has already won lots of praises at home and abroad.

Pre-sales service:

Be a good consultant and assistant to customers, to ensure our customer's investment rewarded

with great profit.

1.Enough details about the ores or slags shall be learned, sometimes a test is needed for some

ores.

2. Equipment of right model is selected for customers.

3. Customized products and processing flow sheet can be designed and developed to meet

customer's special needs,

4. Engineer could be sent to observe customer's working site to come up with an optimized

solution accordingly.

On-sales service:

Every customer is respected and convenience and reliability will be provided. We are devoted to

helping you to benefit as much as possible.

1. Inspection is a must before delivering of the goods.

2. Assistance to make a construction plan by supplying all drawings and data needed.

3. Most favorable scheme for you with the guaranteed quality.

4. Timely communication to make sure improvement of project and your requirement met.

After-sales service:

1. Installation, adjustment, and testing of equipment is available.

2. Train of technicians and workers at site is promised.

3. Service engineers will not leave until ensuring the whole line running well after the installation & adjustment is finished.

4.If any failure or question about the machines or the processing line, contact us and we are

available at any time.

Warmly welcome you come to visist our factory.

Our factory located at Ganzhou city, Jiangxi province, China.

Take flight from your country to Guangzhou airport in China, and then take flight from Guangzhou-- to Gan zhou airport, then we will send the car to pick up you from Ganzhou airport.

- Size: 1.36

- Place of Origin: China

- Brand Name: hengzhong

- Model Number: XMQ460 * 600

- Weight: 560.000 kg

- :

- :

- :

- :

- :

- :

- :

- :

- :

- :

technical parameters

name | unit | ||||||

Cylinder(dia × length) | Φ460×600 | Mm | |||||

Cylinder volume | 100 | L | |||||

Cylinder speed | 48 | r/min | |||||

Feed Particle | 2-5 | mm | |||||

Feeding amount of each time | 15-30 | kg | |||||

Processing Capacity | Particle | 0.83 | 0.30 | 0.21 | 0.15 | 0.074 | Mm |

Mesh Size | 20 | 48 | 65 | 100 | 200 | mesh | |

Capacity | 350 | 274 | 130 | 90 | 45 | Kg/h | |

Dimension | 1600/850/1000 | Mm | |||||

Weight | 560 | kg | |||||